Research and Development

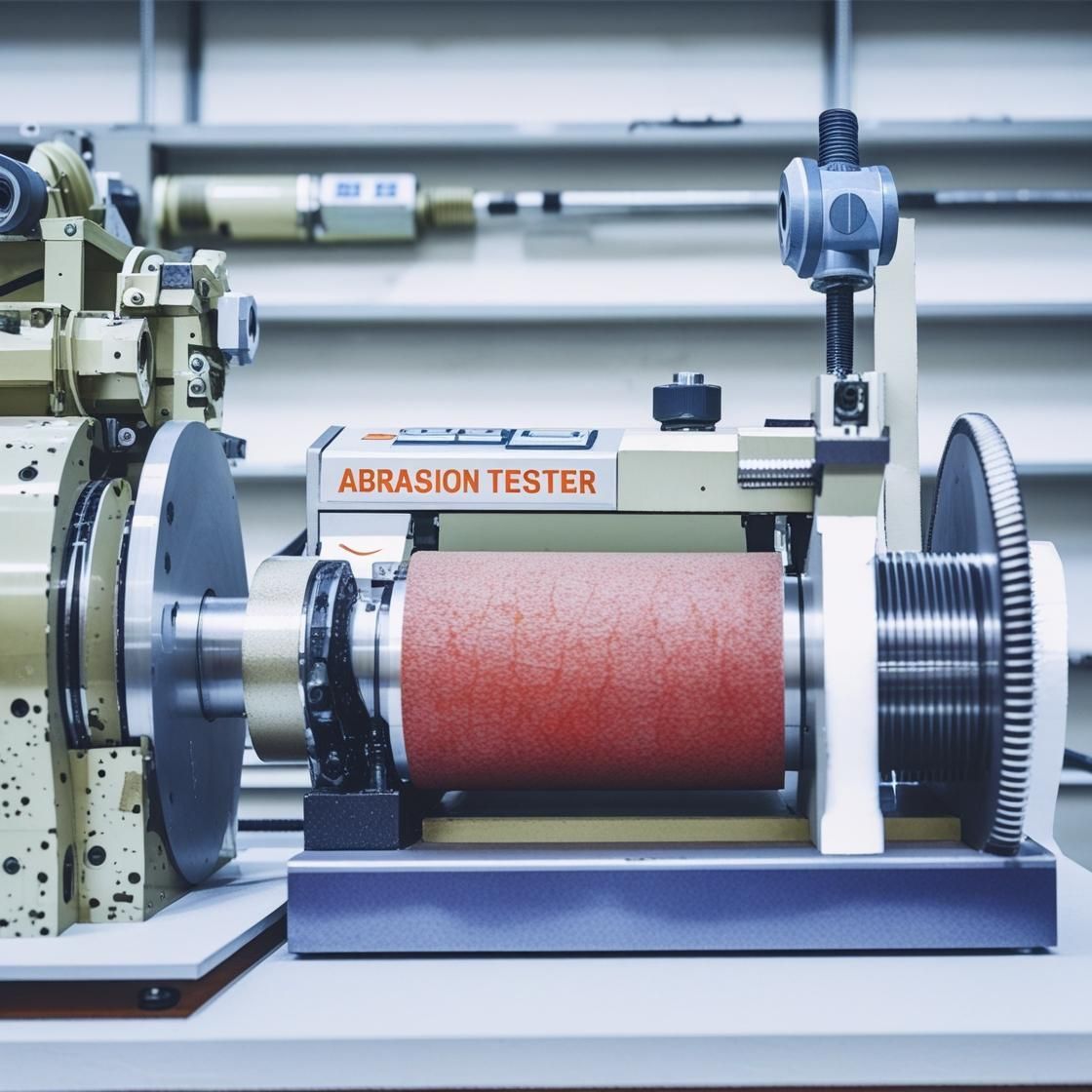

ที่ Chang Rubber แผนกวิจัยและพัฒนาของเรา มีบทบาทสำคัญในการขับเคลื่อนนวัตกรรมและคุณภาพ เรามุ่งเน้นการพัฒนาสูตรยางประสิทธิภาพสูงที่ตอบโจทย์การใช้งานเฉพาะด้าน โดยคำนึงถึง ความทนทาน ความปลอดภัย และการปฏิบัติตามมาตรฐานสากล

ด้วยการทดสอบอย่างต่อเนื่อง การวิเคราะห์คุณสมบัติวัสดุ และการปรับปรุงกระบวนการผลิต เราสามารถส่งมอบโซลูชันที่เชื่อถือได้เพื่อตอบสนองต่อความต้องการที่เปลี่ยนแปลงตลอดเวลาของอุตสาหกรรมระดับโลก

Rubber Sheet Properties

Chemical Resistance Chart